High-quality suppliers around you

High-quality suppliers around you

The domestic computer-controlled electronic universal testing machine started in the early 1990s. Our company is one of the enterprises that absorbs foreign leading technology and develops and develops the electronic universal testing machine. In order to improve the technical level of the company's products, the company has successively absorbed advanced technologies at home and abroad, making the company's product technology level leap to a new level.

The test machine adopts servo motor as the power source; adopts advanced chip integration technology, professionally designed PCI data acquisition, amplification and control system, the test force, deformation amplification, A/D conversion process realizes dual display control and full digital display Adjustment. This machine can test and analyze the mechanical properties of various metals, non-metals and composite materials, and is widely used in aerospace, petrochemical, machinery manufacturing, wires, cables, textiles, fibers, plastics, rubber, ceramics, food, Pharmaceutical packaging, aluminum-plastic pipes, plastic doors and windows, geotextiles, films, wood, paper, metal materials and manufacturing industries can automatically obtain the maximum test force value, breaking force value, Yield strength, upper and lower yield strength, tensile strength, compressive strength, elongation at break, tensile modulus of elasticity, flexural modulus of elasticity and other test data.

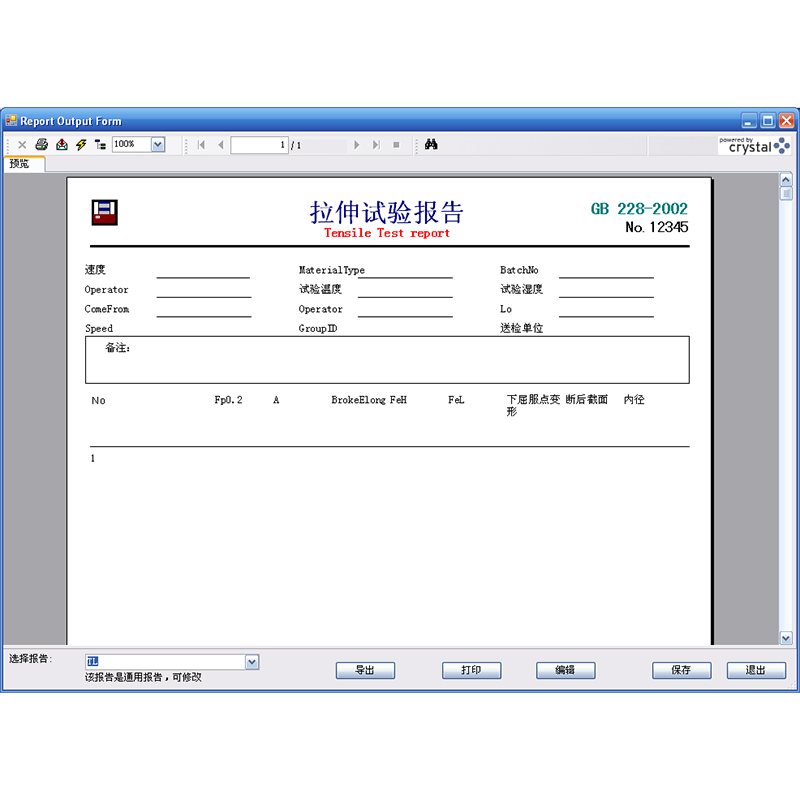

It meets the requirements of national standards GB/T228-2002 "Metal Materials - Tensile Test Method at Room Temperature" and GB/T7314-1987 "Metal Compression Test Method", and meets the data processing of GB, ISO, ASTM, DIN and other standards. Can meet user requirements and standards provided.

1.Host: The machine adopts a desktop double-space structure, which can be pulled up and down, and the beam can be lifted and lowered steplessly. The test space can be changed after replacing the column, lead screw, and cover. The transmission system is composed of a special reducer for servo control, a circular arc synchronous toothed belt, and a lead screw pair, with stable operation, high efficiency and low noise. No pollution.

2.One pair of rubber tension clamps, one pair of compression center disc clamps

1. Using servo motor, stable and reliable performance, with overcurrent, overvoltage, overspeed, overload and other protection devices. The speed ratio can reach 1:5000.

2. The electrical control circuit refers to international standards and conforms to the national testing machine electrical standards, with strong anti-interference ability, which ensures the stability of the controller and the accuracy of experimental data.

3. Condition storage: test control data and sample conditions can be made into modules, which is convenient for batch testing

4. Automatic speed change: The speed of the moving beam during the test can be changed automatically according to the preset program, or manually.

5. Automatic calibration: the system can automatically realize the calibration of the indication accuracy

6. Process realization: the test process, measurement, display and analysis are all completed by the computer

7. Batch test: for samples with the same parameters, it can be completed in sequence after one setting

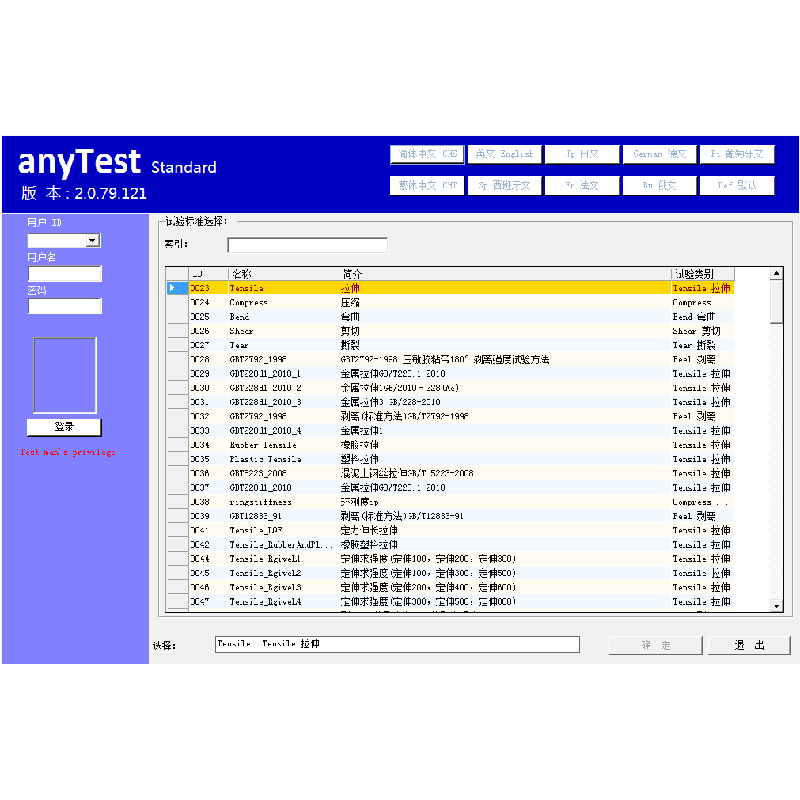

8. Test software: Chinese WINDOWS interface, menu prompts, mouse operation

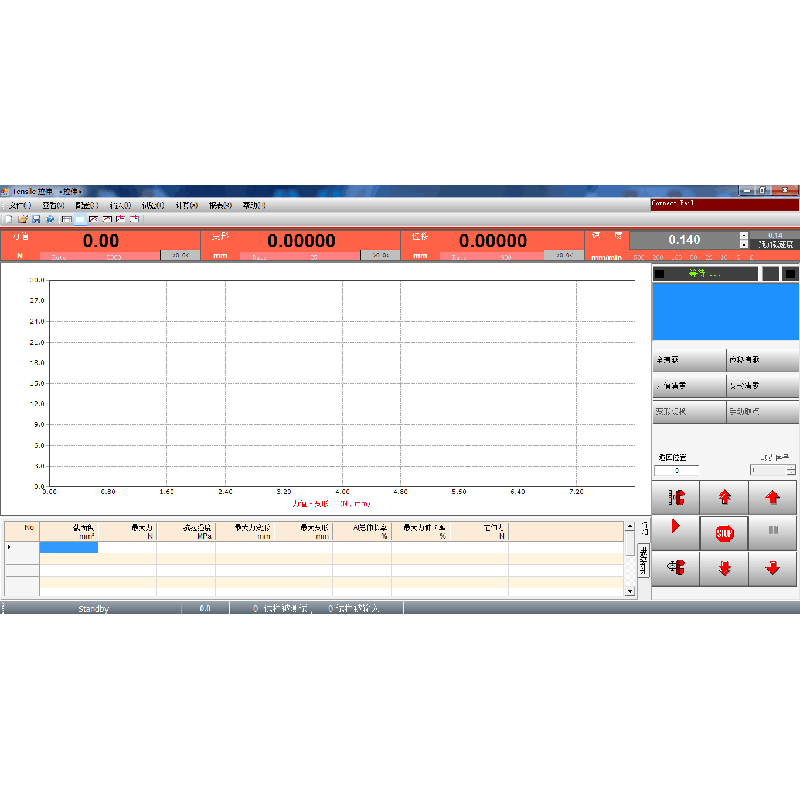

9. Display mode: data and curves are dynamically displayed with the test process

10.Curve traversal: After the test is completed, the curve can be re-analyzed, right-click in the curve display window, and the graphic operation will pop up

11. Menu:

12. Curve selection: stress-strain, force-displacement, force-time, displacement-time and other curves can be selected for display and printing as required

13. Test report: The report can be prepared and printed according to the format required by the user; it has a network interface, which can transmit, store, print and print data, and can be connected to the intranet or the Internet.

14. Limit protection: programmable and mechanical two-level limit protection

15. Automatic stop: After the sample is broken, the moving beam will stop automatically

16. Overload protection: when the load exceeds 3-5% of the maximum value of each gear, it will automatically stop

17. Obtain test results in two modes, automatic and manual, and automatically form reports, making the data analysis process simple.

1.Maximum test force: 5KN

2. Test force measurement accuracy: ±0.5%

3. Displacement resolution: 0.001mm

4. Displacement speed control range: 0.02mm/min ~ 500mm/min keyboard input

5. Tensile test space: 0~1000mm

6. Maximum width of test space: 0~400mm

7. Large deformation extensometer: 25mm gauge length, 20% deformation, 0.5 precision extensometer

8. Power supply power: 0.4kW, 220V, 50Hz

9. Working environment: room temperature 10~35℃, humidity 20%~80%

One set of 1.10000N host (including two sets of Taiwan Shangyin ball screws)

2.A set of AC servo motor

3. A high-precision load sensor

4.WINDOWS compatible control software

5. A pair of universal tensile clamps

6. A computer

7. Large deformation extensometer